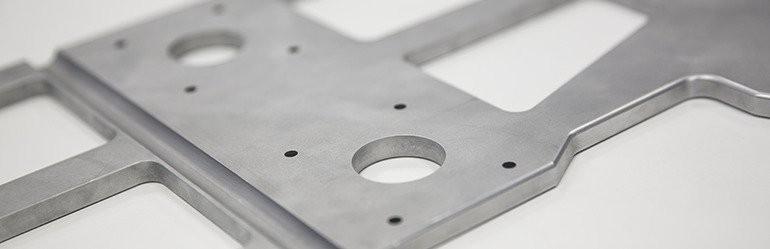

What is the Iridite NCP passivation process?

Iridite is a range of chrome-free conversion coatings, developed by MacDermid Enthone, to provide excellent corrosion resistance properties as well as enabling enhanced adhesion for paints and powder coatings. Other non-chromate passivation processes provide an excellent surface for adhesion but do not rate as highly for corrosion protection. Use of Iridite as a pre-treatment means that even non-powder coated areas of the metal are protected against corrosion.

Iridite NCP is a pre-treatment for powder coating but it can be used as a final finish.

Benefits of Iridite NCP

High resistance to corrosion, suitable as a final finish, leaving parts with a silver appearance.

Excellent adhesion for paints, sealants and adhesives.

Good level of electrical conductivity and often used on applications involving electrical grounding.

Withstands high temperatures up to 350 degrees C - suitable for items with high operating temperatures such as automotive engine components.

Metal coated with Iridite can be spot welded or shield arc welded

Environmentally compliant– contains no hexavalent or trivalent chromium compounds, lead, cadmium, mercury or PBB/PBDE compounds, meeting ELV, RoHS and WEEE standards

Specifications

ROHS compliant

Qualified under MIL – DTL – 5541 TYPE II CLASS 3 and MIL – DTL – 81706